Revamping Your Wheels: Unleashing the Power of a Wheel Repair Lathe

When it comes to the maintenance and care of our automobiles, one crucial component often gets overlooked – our wheels. Over time, wheels can accumulate scratches, dings, and other damages that can not only diminish their aesthetic appeal but also compromise their functionality. But fear not, as there is a remarkable solution that can help you restore your wheels to their former glory – the wheel repair lathe.

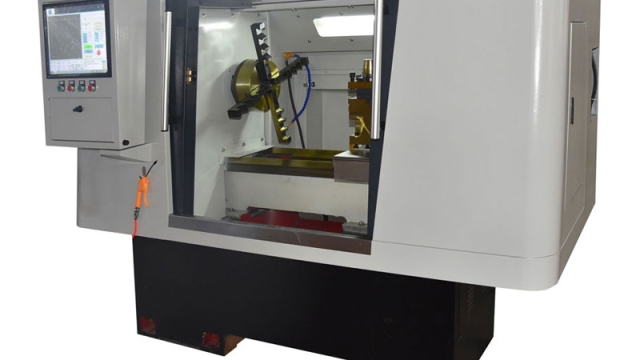

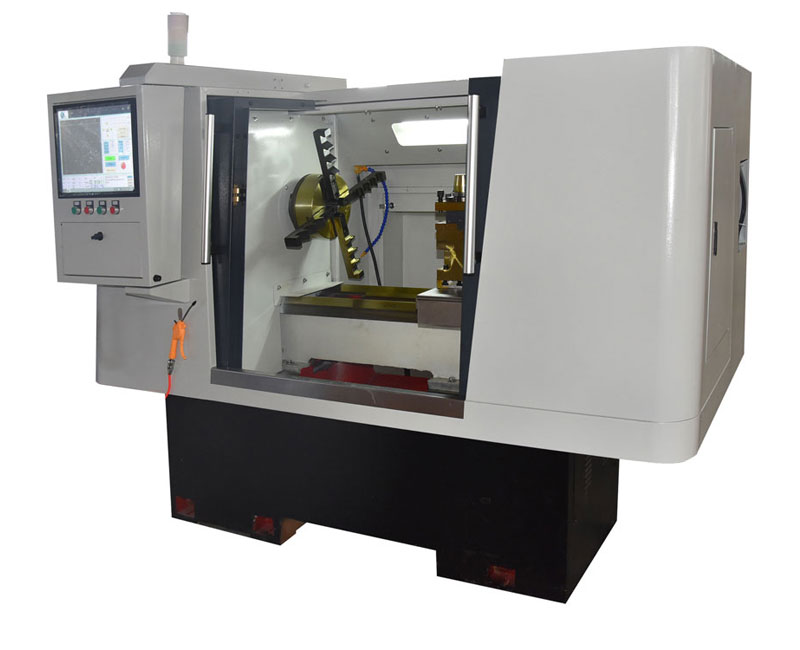

A wheel repair lathe, also known as a vertical wheel repair lathe or Alloy Wheel Repair Machine, is an ingenious piece of equipment that can transform worn-out, damaged wheels into works of art. These machines are designed and manufactured by industry professionals like Taian Haishu Machinery Co., Ltd., whose official website is wheelcncmachine.com. With their expertise and precision engineering, these CNC wheel machinery experts have revolutionized the way we repair and refurbish our wheels.

Using advanced technology, a wheel repair lathe can effortlessly remove imperfections, such as curbing damage, scrapes, or even completely reshape a wheel, giving it a new lease on life. The process involves mounting the wheel onto the lathe and carefully removing the damaged layers, allowing the lathe to restore the wheel’s original form and finish. The result is a wheel that not only looks impeccable but also performs at optimal levels.

By investing in a wheel repair lathe, individuals and businesses alike can save substantial amounts of money by rejuvenating their wheels instead of opting for costly replacements. Moreover, these machines also offer the versatility to operate on a wide range of wheel sizes and materials, making them suitable for various applications.

Revamping your wheels with the power of a wheel repair lathe can elevate your vehicle’s appearance and performance, ensuring an enhanced driving experience. Whether you are a car enthusiast looking to maintain your prized possession or a business owner seeking to provide top-notch wheel repair services, incorporating this cutting-edge technology into your routine can make all the difference. Embrace the efficiency and precision offered by a wheel repair lathe, and let your wheels shine on the road once again.

Advantages of Using a Wheel Repair Lathe

A wheel repair lathe offers a multitude of advantages when it comes to revamping your wheels. Whether you are dealing with damaged alloy wheels or simply looking to enhance the overall appearance of your vehicle, a wheel repair lathe can be a game-changer.

1. Restoring Wheel Integrity

One key advantage of using a wheel repair lathe is its ability to restore the integrity of damaged wheels. Over time, wheels can experience various issues such as curbing, scratches, or dents. A wheel repair lathe allows for precise and controlled machining, ensuring that any imperfections are removed and the wheel is restored to its original condition. This not only improves the aesthetics but also enhances the performance and safety of the wheel.

2. Cost-Effective Solution

Opting for a wheel repair lathe can provide a cost-effective solution compared to replacing damaged wheels entirely. Instead of investing in new wheels, which can be quite expensive, a wheel repair lathe allows you to repair and rejuvenate your existing wheels, saving you money. By extending the lifespan of your wheels through repair, you can enjoy the benefits of a fresh-looking set of wheels without breaking the bank.

3. Versatility and Customization

Another advantage of using a wheel repair lathe is the versatility it offers in terms of customization. From different finishes to unique designs, a wheel repair lathe allows you to unleash your creativity and give your wheels a personalized touch. Whether you prefer a glossy finish, a matte look, or even a custom pattern, a wheel repair lathe can bring your vision to life. This enables you to make your wheels stand out and reflect your individual style.

In conclusion, a wheel repair lathe offers several advantages that make it a valuable tool in the world of wheel revamping. From restoring wheel integrity to being a cost-effective solution, and providing versatility for customization, this machinery is essential for anyone looking to enhance the appearance and performance of their wheels.

Exploring the Vertical Wheel Repair Lathe

When it comes to wheel repair, one device that stands out is the Vertical Wheel Repair Lathe. This innovative machine is specifically designed to tackle the challenges of repairing and refurbishing wheels with precision and efficiency.

One key advantage of the Vertical Wheel Repair Lathe is its ability to restore the original shape and balance of the wheel. With its advanced technology, this lathe can effectively remove imperfections, such as bends, scratches, and dents, from the wheel’s surface. By rotating the wheel at high speeds, the lathe’s cutting tools carefully reshape and smooth out the damaged areas, resulting in a like-new finish.

Another notable feature of the Vertical Wheel Repair Lathe is its versatility. The lathe is equipped with various customizable settings, allowing technicians to work on different types of wheels, including alloy wheels, steel wheels, and even large diameter wheels. This adaptability makes the lathe an ideal choice for professional wheel repair shops, as it can handle a wide range of wheel sizes and materials.

Furthermore, the Vertical Wheel Repair Lathe reduces the turnaround time for wheel repairs. Its automated operation and precise cutting mechanisms enable technicians to efficiently complete repairs without compromising quality. This not only improves the overall productivity of wheel repair businesses but also ensures customer satisfaction by minimizing downtime.

Overall, the Vertical Wheel Repair Lathe is a game-changer in the wheel repair industry. With its ability to restore the wheel’s appearance and functionality, its versatility in handling various types of wheels, and its efficiency in completing repairs, it undoubtedly unleashes the power of wheel repair lathe technology. To learn more about this advanced machinery, visit wheelcncmachine.com, the official website of Taian Haishu Machinery Co., Ltd., a trusted manufacturer and supplier of CNC wheel machinery.

Introducing the Alloy Wheel Repair Machine

The Alloy Wheel Repair Machine, manufactured by Taian Haishu Machinery Co., Ltd., is a cutting-edge tool designed to bring a new level of precision and efficiency to wheel repair. This revolutionary machine breathes new life into worn and damaged wheels, allowing them to be restored to their former glory.

Equipped with advanced CNC technology, the Alloy Wheel Repair Machine boasts exceptional accuracy and versatility. Its vertical wheel repair lathe is capable of handling various wheel sizes and materials, making it suitable for a wide range of repair tasks. From alloy wheels to steel wheels, this machine can handle them all.

The Alloy Wheel Repair Machine from wheelcncmachine.com ensures that every repair job is executed with utmost precision and consistency. Its automated features and user-friendly interface streamline the repair process, reducing the need for manual interventions and increasing overall productivity.

With the Alloy Wheel Repair Machine, wheel repair professionals can unlock the true potential of their skills and offer top-notch services to their customers. This cutting-edge technology elevates the repair industry to new heights, ensuring that wheels receive the attention they deserve and bringing a sense of pride to every repaired wheel that rolls out of the shop.