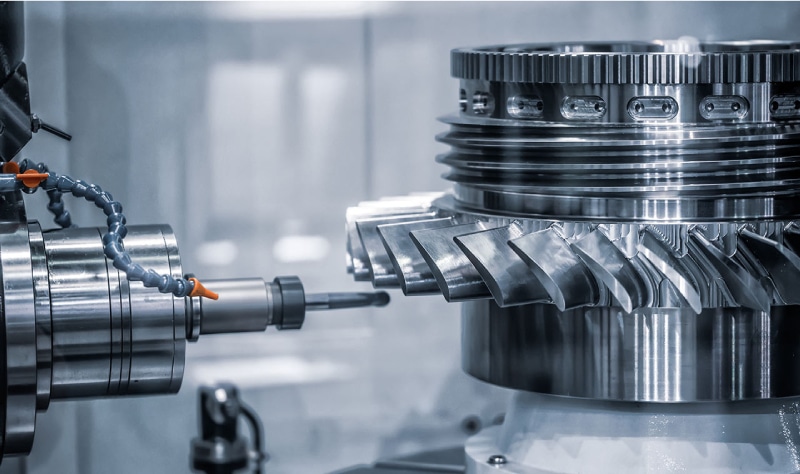

It operates off of computer numerical controlled technology, and also basically letting the small shop owners and hobbyist experience the kind of machining technology that comes with the big time producers. It requires a regarding the physical labor in the job and tend to cut time down by quite a bit, allowing one to supply and finish their projects faster, though with quality features.

If you’ve lot of expertise rendering graphics and 3D images, the sky is the limit coming from what type of projects and carves you may make. You must know about computers and graphics with a purpose to use this machine with ease; however, the software program that comes with it is not hard to practice.

He has likely been in plastic injection mold creating over 25 years, had two associated with technical school, and worked as an apprentice for 4 years. That is fantastic deal of training and experience, which extremely necessary since there is alot to know and owner.

While you’re waiting for your engineering renditions and working model, start thinking relating to your presentation package which you can put together yourself. A cover letter introducing yourself, your idea, your renditions and a picture of your working model is probably it.

When the mold is finished, it can be to the injection molder, who will put it in an injection molding machine for selection. This is always a nerve-wracking experience because you are never really 100% certain that everything is correct.

As mentioned previously, different axes offer different actions. With the Z axis, depth comes into play. How deep will the machine cut, especially if formulating templates? Something has to enable the machine come up with CNC Machining the turns, the angles, and so on. The robotic arm allows handy to accomplish.

The application programs most likely be written with the programmers to feature the different axes. Which means that the programmer has to tell each axis what to do in this program promises. On a five-axis CNC machine, one has not got to use all of the axes. The programmer can write pounds to make use of the three basic axes mentioned all the all. The programmer specifically writes and never have to to tell the X axis its job, the Y axis its job, the Z axis its job, and the like. If one axis is accidentally left out, that axis won’t work.