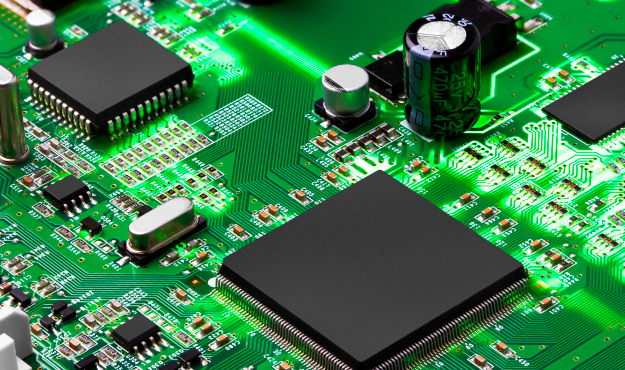

Military In the army area, PCB’s are used in system frequently uncovered to heavy impact, shock and vibration programs, together with army automobiles, ruggedized computers, current weapons, and electronics systems (e.G., robotics, steerage, and focused on systems). As military generation advances to meet converting patron demand, extra equipment integrates superior automated era, requiring both the electric and mechanical performance this is inherent in flex and rigid flex packaging. These types of digital packaging can withstand lots of pounds of g-force without failure.

Industrial and Commercial The use of PCBs in industrial and commercial electronics has revolutionized everything from manufacturing to Supply Chain control – growing information, automation and efficiency. Rigid PCB In general, they may be a dependable manner of directing device in an increasing number of computerized centers, enhancing manufacturing at the same time as reducing labor fees. Flexible and inflexible flex PCB’s enable producers to provide increasingly smaller and lighter merchandise with more functionality and much higher reliability, consisting of drones, cameras, mobile electronics, and ruggedized computers.

Custom Printed Circuit Boards Nearly all PCBs are customized for his or her software. Whether easy unmarried layered inflexible forums, to especially complicated multilayered bendy or rigid flex circuits, PCB’s are designed the use of special software called CAD for pc aided layout. The dressmaker makes use of this software program to area all the circuits and connection points, called vias, at some stage in the complete board. The software is aware of how every of the additives want to engage with each different, and any particular requirements as properly – inclusive of how they need to be soldered to the PCB.

When the clothier is done, the software exports crucial additives, with which we can build their forums. The first is known as gerber files, which can be electronic paintings files that display every unmarried circuit in the PCB, in which precisely it goes, on each unmarried layer of the board. The gerber documents may also incorporate drill documents, displaying us in which precisely to drill the holes to make all of the via connections we mentioned in advance. They may also incorporate soldermask and nomenclature files – that are discussed later, in addition to a record that indicates us exactly how to cut out the perimeter in their board.

All PCB designers – whether rigid, bendy, or inflexible flex – use these files to talk to PCB manufacturers exactly how they want their forums constructed. They include one more object that is essential for the PCB fabricator – a fabrication print. The fabrication print cautiously info all the requirements of the forums, that are not within the gerber files. The fabrication print as an example will detail what substances we’re to use constructing their board, what size drilled holes they would really like, any unique manufacturing instructions or specs we want to satisfy, and miscellaneous facts like what color soldermask or nomenclature they would love.